Exactly How an Optical Fibre Diameter Analyser Improves Quality Assurance in Fibre Production

The combination of an Optical Fibre Diameter Analyser into Fibre production processes stands for a significant innovation in quality control methods. By using real-time, precise dimensions of Fibre diameters, this modern technology deals with the critical demand for consistency in manufacturing criteria.

Significance of Fibre Diameter Dimension

Exact measurement of Fibre Diameter is important in the field of optical Fibre technology, as it directly influences the efficiency and reliability of Fibre optic systems. The Diameter of an optical Fibre impacts its light-carrying ability, attenuation, and total transmission efficiency. Precision in determining Fibre Diameter makes certain that the optical properties are maintained within specified tolerances, which is important for optimum signal integrity.

Variations in Fibre Diameter can result in enhanced losses because of spreading and modal dispersion, impacting the top quality of data transmission. In high-speed interaction systems, such disparities can result in substantial degradation of signal top quality, leading to data mistakes and decreased efficiency. Additionally, regular Fibre Diameter is necessary for compatibility with adapters and splicing innovations, which are essential components of Fibre optic networks.

Quality assurance procedures in Fibre production greatly count on precise Diameter dimensions to make sure conformity with industry criteria. By applying robust measurement strategies, suppliers can boost item integrity, lessen waste, and improve overall system performance. Therefore, the relevance of Fibre Diameter dimension can not be overstated, as it offers as a keystone in the development of optical Fibre technology and its applications in contemporary communication networks.

Exactly How the Analyser Functions

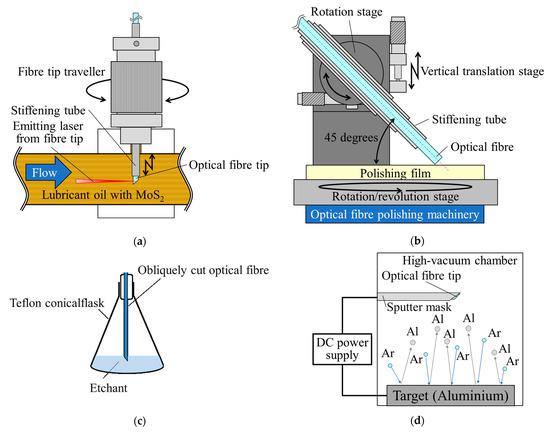

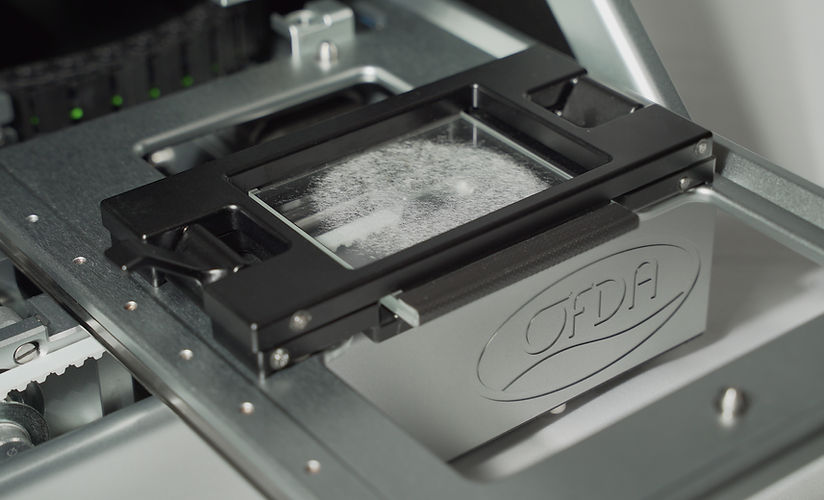

The effective measurement of Fibre Diameter depends on advanced logical strategies that make sure precision and dependability in optical Fibre manufacturing (optical fibre diameter analyser). The Optical Fibre Diameter Analyser utilizes a mix of laser modern technology and progressed image processing formulas to properly analyze the Diameter of fibers as they are produced

At first, a laser light beam is routed at the relocating Fibre, developing a cross-sectional darkness. The analyser catches this darkness making use of high-resolution cameras positioned tactically along the assembly line. The captured pictures are then refined in real-time to establish the Fibre's Diameter with remarkable precision.

The system uses advanced algorithms that represent various aspects, consisting of variants in light intensity and ecological conditions, to enhance measurement integrity. It can discover minute adjustments in Diameter, such as changes that might happen throughout the production procedure.

In addition, the analyser can dealing with multiple fibres at the same time, increasing throughput without compromising accuracy. By giving rapid responses on the Diameter, the Optical Fibre Diameter Analyser plays an important role in maintaining rigorous top quality control requirements, guaranteeing that the final item satisfies sector specifications and consumer needs.

Benefits of Real-Time Monitoring

While typical techniques of keeping track of Fibre Diameter commonly involve taxing post-production checks, real-time tracking considerably boosts the effectiveness and quality of optical Fibre manufacturing. optical fibre diameter analyser. This proactive technique enables producers to recognize variances in Fibre Diameter as they take place, as opposed to waiting up until production is total to evaluate top quality

By continuously measuring the Diameter during production, suppliers can guarantee that the fibers fulfill strict requirements, causing lowered variability and boosted consistency. Real-time tracking additionally enables instant rehabilitative actions to be taken, decreasing waste and stopping malfunctioning fibres from going into the supply chain.

In addition, this technology assists in boosted data collection and analysis, weblink providing understandings right into production fads and potential areas for enhancement. Such data-driven decision-making equips suppliers to optimize processes and keep high requirements of top quality control.

Furthermore, real-time monitoring promotes a culture of constant renovation within the manufacturing setting. Employees are more involved when they can see the impact of their operate in real-time, resulting in increased responsibility and a dedication to quality. On the whole, the execution of real-time surveillance systems in optical Fibre production translates to premium item top quality and raised consumer complete satisfaction.

Influence On Production Efficiency

Implementing optical Fibre Diameter analysers dramatically enhances production efficiency by simplifying the production procedure. These gadgets assist in constant tracking of Fibre Diameter, allowing producers to discover discrepancies in real-time. By identifying inconsistencies promptly, assembly line can be changed rapidly, reducing downtime and reducing the likelihood of producing faulty products.

In addition, the combination of these analysers into the manufacturing process enables better source allotment. With accurate Diameter measurements, drivers can maximize material use, making certain that resources are not squandered on flawed fibers. This precision additionally adds to less junk and remodel, inevitably lowering production prices.

The automation offered by optical Fibre Diameter analysers lowers reliance on hand-operated evaluations, which are vulnerable and typically taxing to human error. Because of this, employees can concentrate on more calculated tasks, improving total performance.

Additionally, the data produced from these analysers can notify process enhancements and promote better decision-making. By examining fads in Fibre Diameter variants, producers can apply proactive steps to boost manufacturing techniques and maintain consistent high quality. In recap, optical Fibre Diameter analysers play an essential role in increasing manufacturing performance, leading to greater high quality result and increased success.

Situation Researches and Success Stories

Throughout numerous sectors, case research studies highlight the transformative effect of optical Fibre Diameter analysers on manufacturing procedures. One noticeable instance is a leading telecommunications company that faced challenges with inconsistent Fibre diameters, resulting in boosted rejection rates. By integrating an optical Fibre Diameter analyser, the company achieved real-time monitoring of Fibre measurements, causing a 30% decrease in issues and significant price financial savings.

Moreover, a research establishment focusing on innovative materials made use of optical Fibre Diameter analysers to refine their speculative processes. The analyser's capacity to offer thorough insights into Fibre uniformity allowed the growth of ingenious products with improved efficiency characteristics.

These success tales emphasize the necessary duty of optical Fibre Diameter analysers in boosting high quality control, boosting production effectiveness, and driving technology across diverse sectors.

Conclusion

In conclusion, the Optical Fibre Diameter Analyser plays a crucial duty in improving top quality control within Fibre manufacturing. As demonstrated through different situation researches, the analyser proves vital for accomplishing remarkable product high quality in Fibre production.

The execution of optical Fibre Diameter analysers allowed for rigorous high quality control, ensuring that the created fibers satisfied exacting sector requirements.In verdict, the Optical Fibre Diameter Analyser plays a pivotal function in boosting high quality control within Fibre production.